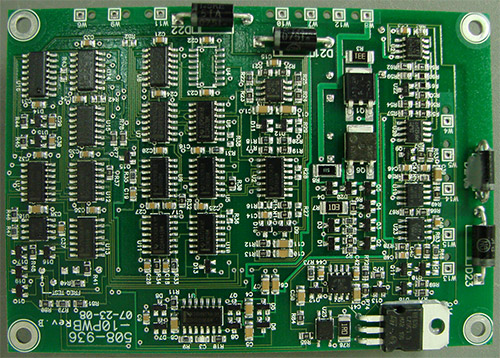

The Best Custom Design of Print Circuit Board (PCB)

Creating a printed circuit board (PCB) or we call it with PCB Assembly that meet all the design requirements can be a very technical and time-consuming process – not to mention expensive. The design engineer is tasked with turning the concept into reality in the Shortest time possible to speed time to market with qualityhttps://bojankezastampanje.com reliable products.

To improve the company’s technologyhttps://bojankezastampanje.com some PCB Assembly Services provides high-quality designs for PCBshttps://bojankezastampanje.com PCB designs are now being streamlined through the use of sophisticated software that helps designers turn ideas into working boards in small amounts of time with the level of confidence that design can be made with intended functionality.

PCB technology continues to grow as electronics are incorporated into existing new product models such as smartphoneshttps://bojankezastampanje.com smart televisionshttps://bojankezastampanje.com droneshttps://bojankezastampanje.com and even refrigerators. This advancement in Electronics requires an increased complexity of circuits with ever smaller footprints that include high density interconnects (IPM) and flex boards.

Advantages of PCB Design Software

Creating PCBs with software designs provides many advantages to engineers:

- In shorthttps://bojankezastampanje.com design software can store previously designs and templates that are commonly used for reuse. Choosing an existing design with time-proven reliability and functionalityhttps://bojankezastampanje.com then adding or editing functions is a quick way to get a project moving forward.

- The software component-vendor library provides a library containing thousands of known PCB components and materials available for inclusion on the board. It can be edited to add new materials that become available or to add custom components as needed. Like the new components offered by the manufacturerhttps://bojankezastampanje.com the Library is updated as it should.

- DRC or design inspection regulation is a powerful tool that examines PCB design for integrity issues related to logical and physical characteristics. This function alone can save a lot of time in removing and validating design boards.

- Intuitive routing tools-place and move routing easy and intuitive. Automatic routing is another important feature that saves time in development.

- Quality-improvement design tools provide more reliable resultshttps://bojankezastampanje.com improve quality.

- The file generation – after the design is completed and validated by the softwarehttps://bojankezastampanje.com the designer has a simple automated method of creating the file the manufacturer needs to produce the product. Some further systems include a file checker function that verifies all files required for production have been generated.

- Time savings – lack or questionable design elements can slow down the production process with questions between manufacturers and designs. Each problem adds to the manufacturing cycle time and can result in reset and higher costs.

- Design for manufacturing – DFM tools integrated into many package designs providing design analysis against manufacturing capabilities. This can save you a lot of time in fine-tuning the design before ever getting to the fabrication process.

- Techniques for changes such as modifications madehttps://bojankezastampanje.com tracked and documented for future reference.

- Collaborative-design software facilitates peer review and advice from other technicians through sharing the design of the entire development process.

- The simple-automatic design process of placement and drag-and-drop functionality allows designers to create and edit designs more efficiently and accurately.

- The software’s documentation generates hard-copy documents for PCB layoutshttps://bojankezastampanje.com schemashttps://bojankezastampanje.com component listshttps://bojankezastampanje.com and more. Manual creation of the document is omitted.

Potential problems caused by not using PCB design software

Most day PCB designers are utilizing multiple levels of software to develop and analyze design boards. It becomes obvious very quickly that there is a considerable loss to not implement a computer-aided design (CAD) tool in PCB design:

Deadlines and slow time to market-competition using such tools as a competitive advantage. Management expects product schedule and within the budget that has been made.

Manual methods and back-and-forth communication with manufacturers hinder the process and increase cost.