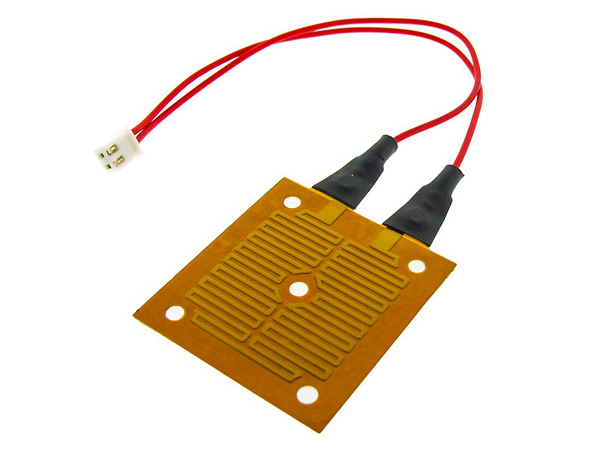

Kapton is an amberhttps://bojankezastampanje.com transparent colored polyimide film. It is used in printed and electronic loops. Howeverhttps://bojankezastampanje.com it also plays a considerable role in variegated settings such as the thermal quilts used in satellites and space probes. It is processed from the precipitation of oxydiphenylamine and pyromellitic dianhydride. Kapton heaters have high pliable muscle which means they can resist a lot of pressure and stress before shattering. Their tear defiance is magnificent.

Kapton heaters have low degassing. This means that the emission of gas that was trapped and dissolved in the making of the material is less. Why is this essential? Degassing can be a big issue if it gathers in a confined space where air moves steadily. The lower the outflowhttps://bojankezastampanje.com the better. A Kapton heater has superb proportional stability. This means that the material can sustain its indigenous form while being used for its predetermined purposehttps://bojankezastampanje.com notwithstanding the temperature exposition.

Despite a Kapton heater having a lightweight and skinny descriptionhttps://bojankezastampanje.com it also has a high-watt weight. This is the real kicker for why the radiator is an excellent way to go. When you acquire a Kapton heaterhttps://bojankezastampanje.com you can be assured that you will get even heat distribution despite its low operating costs. This makes it ideal where weight and space allowances are limited or for extreme temperature environments.

When it comes to installing Kapton polyimide heatershttps://bojankezastampanje.com you have a few alternatives. The most popular is using a pressure-subtle sealant. It offers a robust and pure weld and easily sustains efficient heat exchange. You can install the heater through clamping if needs be. A pressure plate is tightened in place along with an insulation layer or a pressure pad to guard the heater. You must ensure the work surface is smooth and completely clean to ensure even heat distribution. Utilizing a self-fusing tape is the final option. This is a brilliant idea when installing a Kapton heater to a fine discoidal surface. It will still maintain even heat transfer and provide safe operation.

Due to their malleabilityhttps://bojankezastampanje.com Kapton heaters are fitting for both low and high volume applications and in scenarios where surface heating or expeditious heat time is required. Engineers prefer etched foil heaters for applications that need heating but have the difficulty of a lack of space. The heater’s quadrate cross-section puts more of the heating surface in contact with the object being heated and exposes the elements.

What to Look for in Prototype Systems

- Personalized flexible heater prototypes.

- A collaborative process that optimizes both your business and technical requirements.

- Efficient FEMA process to examine application risks.

- Photo tool production and in-house circuit design.

- Controlled state-of-the-art cutting machine that eradicates the need for steel rule.

- Years of experience and agency approvals with approval navigation.

What to Look for in a Production System

- Sub-assemblies and components structured to increase the velocity of your production line.

- Built-in quality checks with consumer-specific attributes.

- Firm document control system to lock down the prototype result.

- ISO 9001 certified system.

Conclusion

Kapton heaters are ideal for unfavorable temperature habitats. Their heating elements are designed with a lightweighthttps://bojankezastampanje.com flexible organic polymer with dielectric potential. The polymer also provides superior resistance to most radiationhttps://bojankezastampanje.com oilshttps://bojankezastampanje.com and solvents.